The aerospace industry has some of the most stringent requirements for metalworking fluids. They need to perform at the highest level with the right amount of lubricity, stability, foam control, multi-alloy compatibility, and cleanliness. Aerospace metalworking fluids also need to meet government and industry-specific standards on top of customer-specific requirements, and must be cost-effective. Different aerospace companies have different requirements, including corrosion, compatibility, and chemical restrictions.

Soluble oils are often used in machining hard metals, and in the past they contained active sulfur to help achieve the lubricity needed for the desired results. Active sulfur may attack certain metals, which was bad for the machines, and could damage the part being cut. In addition, the odor created by the active sulfur was extremely unpleasant and made it difficult for machinists and CNC operators to comfortably do their jobs.

Our research and development department began investigating ways to create a metalworking fluid for aerospace that would provide the same or better lubricity, without the use of chlorine, sulfur, or mineral oil. We spent several years creating and testing different combinations of ingredients and technologies to create a fluid that would provide the needed lubricity while protecting the machinery and providing increased comfort for workers. We also invested in third-party testing and approvals to make sure we were delivering the best possible fluid for aerospace metalworking.

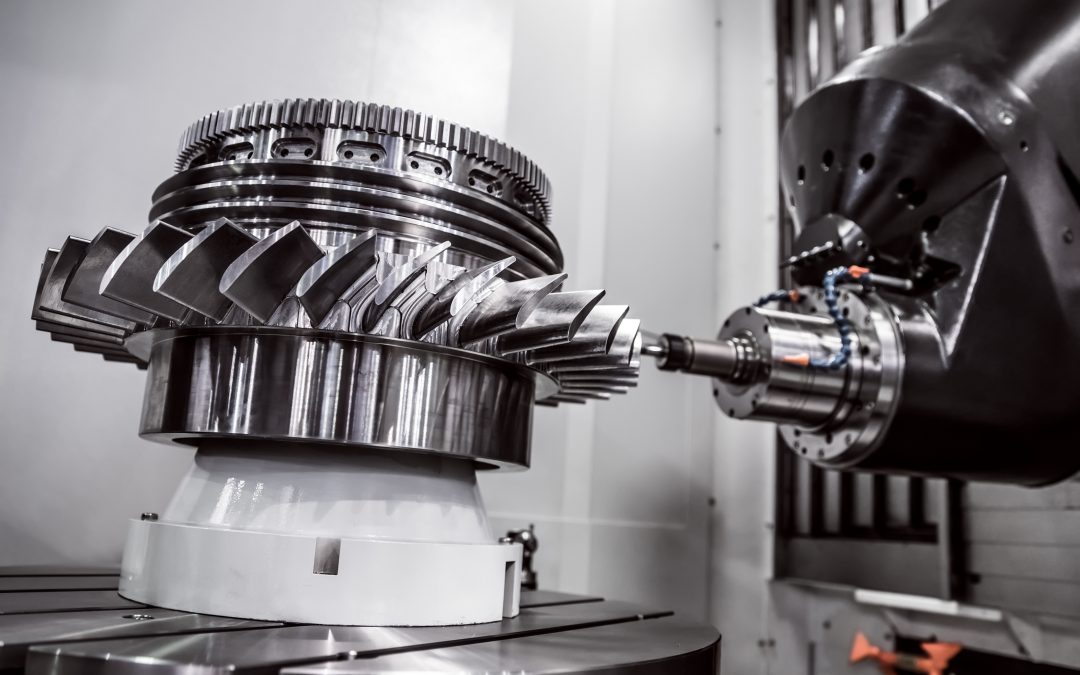

The result was Master Fluid Solutions’ HyperSol 888NXT. Currently, the metalworking fluid industry has synthetic, semi-synthetic, micro emulsions, emulsions, and straight oils. Master Fluid Solutions’ patented HyperSol 888NXT does not fit in any of those categories. We’ve created an entirely new category of fluid. It is ideal for machining hard metals, which can include various grades of stainless steel, titanium alloys, and nickel-based alloys, but also provides both incredible levels of lubrication and an extremely high rate of cooling. This has never been done before in metalworking fluids, as those are typically polar opposites.

While HyperSol 888NXT is designed for the aerospace industry, it is also an ideal metalworking fluid for any complex, high-tech industry that requires high pressures and faster speeds, including medical, automotive, nuclear components, or the energy sector. We’ve even found that usage is lower with less disposal, and less downtime for cleaning machines is needed. This — combined with longer tool-life and lower cycle times — can lead to significant cost savings.

We will begin offering HyperSol 888NXT soon. For more information, contact your local distributor.