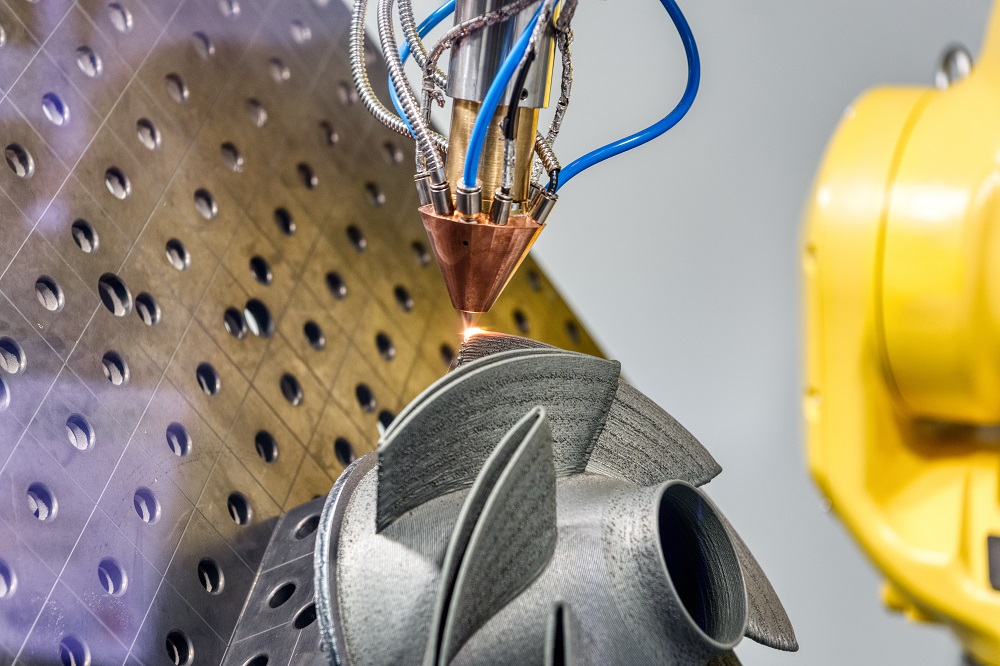

Additive manufacturing (AM), also known as 3D printing, has come a long way since its inception in the 1980s. AM allowed manufacturers to rapidly create and test prototypes for part and component designs.

As materials became stronger and processes more efficient, manufacturers began to use the technology to mass-produce parts with complex geometries. Today, 3D printing has matured into a production process that can build working components out of different feed stocks that can be stronger than conventional materials.

It’s no surprise that the AM market generated over $10.4 billion in revenue in 2019 — and by the end of this decade, it’s projected to grow to more than $55 billion. Far from a trend, AM is the future of manufacturing.

America Makes: Forging the Future of Manufacturing

The National Center for Defense Manufacturing and Machining (NCDMM) fosters industry-wide collaboration to enhance the U.S. manufacturing industry and workforce. That’s why, in the last several years, the organization turned its focus to AM, paying close attention to how the process can reshape the domestic supply chain. So in 2012, they founded America Makes, the leading industry consortium for 3D print and additive manufacturers.

The organization provides a platform for government, academic, non-profit, and cross-company collaboration to research and innovate AM technology, plus train the next generation of the workforce and build bridges across industries to speed up the adoption of AM.

The First Metalworking Fluid Manufacturer to Embrace AM

Master Fluid Solutions is proud to be a member of America Makes, helping to shape the future of U.S. manufacturing. To date, the company is the only metalworking fluid manufacturer to join America Makes.

Founded on improving sustainability in the manufacturing industry by streamlining processes and eliminating waste has always been a guiding principle at Master Fluid Solutions, Master Fluid Solutions created the first-ever commercial fluid recycler, XYBEX, in 1970, which quickly made coolant recycling an industry standard. As a member of America Makes, Master Fluid Solutions will contribute to support sustainable AM technology research, as well as participate in knowledge sharing.

It’s worth noting that mixed and hybrid manufacturing environments often use both conventional subtractive techniques and additive manufacturing — and Master Fluid Solutions offers the leading cutting fluids for multi-material compatibility. For instance, TRIM® C390 and TRIM® MicroSol® 692XT are both formulated for superior performance with multi-metal and composite materials. TRIM® HyperSol™ 888NXT, the company’s first biopreferred coolant, is the most versatile product on the market for machining tough titanium and Inconel® metals, improving tool life and well suited for hybrid manufacturing situations — all at lower concentrations and reducing carry off compared to conventional fluids.

As hybrid and AM shops become more common in the future, Master Fluid Solutions expects to develop additional fluids specifically for AM. For more information or a trial of our products, call +1 800-537-3365 or email us at [email protected].