Manufacturing technology, environmental laws, and consumer demand are changing dramatically, and practices considered normal now might be antiquated by 2030.

The unprecedented disruption of the global supply chain in 2020 exposed how vulnerable our economy really is. Manufacturers in the US are increasingly focused on reshoring production of critical supplies to avoid future crises. Freightwaves reports as many as 200,000 overseas manufacturing jobs could return to the United States by the end of 2022.

The 2021 State of North American Manufacturing Report by Thomas offered even more hopeful numbers. A survey of North American manufacturers found 83% of respondents are likely to reshore their production, up from 54% in 2020. This massive influx of manufacturing could drive as much as $443 billion in economic opportunity — especially for the metalworking sector.

Any manufacturer looking to increase their revenue has an amazing chance to do so, if they make the necessary effort to diversify their operations. Diversification isn’t just important for capturing some of the opportunity in this reshoring campaign — it’s critical to future-proofing an operation and safeguarding from upcoming market shifts. Here’s how manufacturers can quickly expand their offerings:

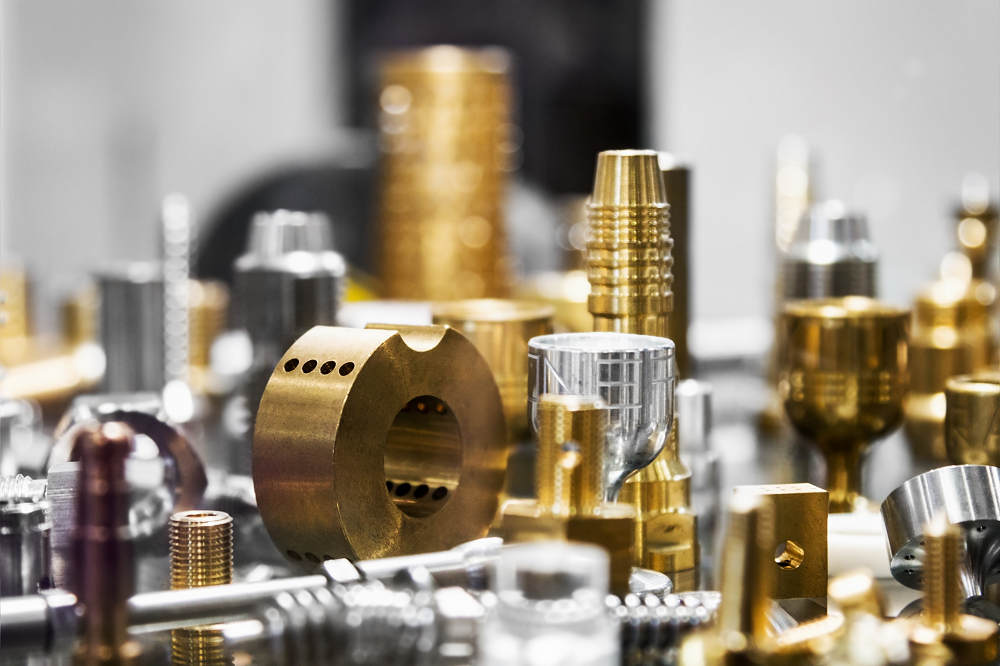

Offer Wider Variety of Parts

The fastest way to diversify is to try to create new revenue opportunities from your operation. Carefully assess the machinery and materials you already work with to see if they can make additional types of parts and components, or invest in machinery as needed. These new offerings could be sold to existing customers, or form the basis of a sales campaign that draws in new clients. As these capabilities grow your business, it could spur investment in even more equipment or technology.

Tap New Markets

When assessing your existing machinery and materials, you should not only think about additional parts they could make in your existing market, but also consider possibilities in completely new sectors. At the onset of the COVID-19 pandemic, many metalworkers pivoted into the medical device manufacturing industry to provide much-needed ventilators. Carefully research other markets facing a gap that your capabilities could fulfill.

Incorporate Additive Manufacturing

Many manufacturers are diversifying by adding additive manufacturing to their portfolio. This helps with prototyping, or fulfilling small orders of complex parts and components. Additive manufacturing can supplement your production operation.

Change to More Versatile Cutting Fluid

Manufacturers often try to get by with low-price cutting fluids. These can lower productivity and actually increase costs and coolant spend. Many inexpensive fluids are only compatible with a few operations or materials. As manufacturers try to diversify, their cutting fluids may be holding them back. Eliminate that complication by investing in advanced, highly versatile cutting fluids like biobased TRIM® HyperSol™ 888NXT, aerospace-approved TRIM® C390, and TRIM® MicroSol® 692XT. All three offer incredible performance and compatibility with a wide array of materials, plus superior tool life and ease of maintenance.

Any diversification effort is likely to come with practical challenges and unforeseen expenses. For example, the shortage of skilled labor can create challenges when taking on additional work. In other cases, machinery may need repair or upgrades and automation can help address the labor shortage. The best thing any manufacturer can do in these circumstances is anchor as much of their budget as possible to offset unexpected costs and make diversification as seamless as possible. Investing in the right cutting fluid is key, as it can impact throughput, labor efficiency, and overall productivity.

To learn more about choosing and managing the best coolants for diversifying your production shop, call +1 800-537-3365 or email us at [email protected].