After a period of decline, the aerospace manufacturing industry has not only recovered but is growing faster than ever. In 2020, the market reached a record high of $298 billion. Spurred by renewed interest in air travel and a reignited space race between companies like Blue Origin, SpaceX, and Virgin Galactic, this valuation is expected to nearly double to $573.6 billion by 2030.

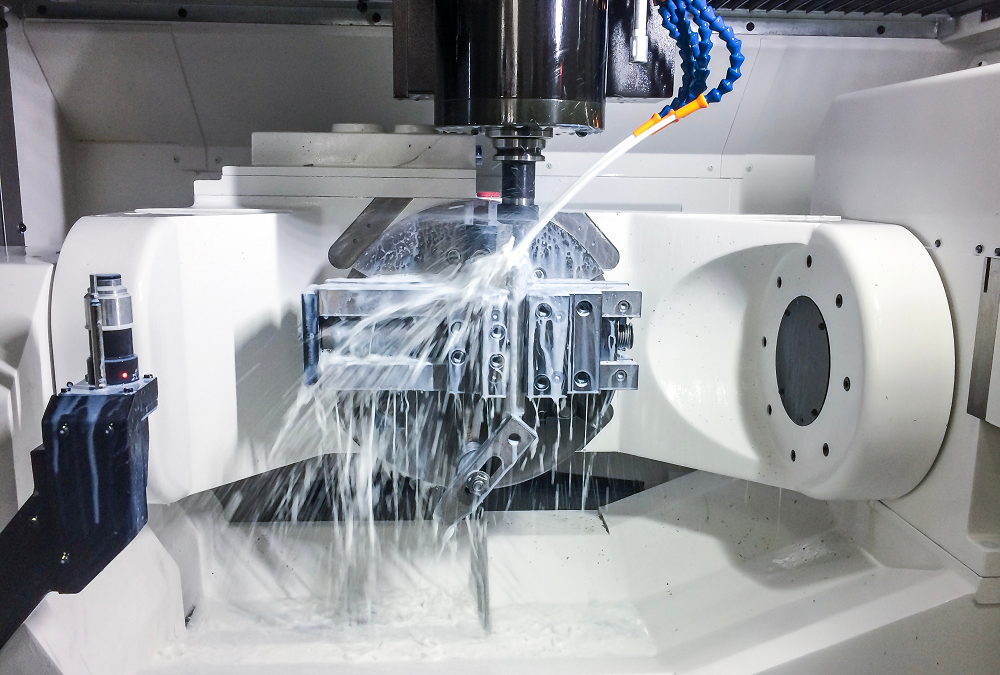

There is an incredible opportunity for parts and components manufacturers looking to become suppliers for aerospace original equipment manufacturers (OEMs). However, because there are many risks involved in transporting people through the air (or space), the industry is highly regulated to ensure the highest levels of safety and quality. The intense oversight even extends to the type of metalworking fluid suppliers use to produce parts and components.

To protect themselves, OEMs maintain their own compliance programs and will only allow suppliers to use materials they’ve thoroughly vetted and officially approved. While this should be clear, many metalworking fluid manufacturers market their products as approved or meets the requirements of an aerospace manufacturer. So, what do these designations mean and why is it so important for suppliers to be careful about which fluids they choose?

What’s the Difference Between “Approved” vs “Meets Requirements?”

Many aerospace manufacturers and OEM’s in the medical industry have their own set of standards their suppliers must adhere to, ranging from manufacturing techniques to the type of materials they use. Additionally, each company maintains a select list of approved cutting fluids for specific operations that have been evaluated by their labs.

To attain these approvals, metalworking fluid makers must submit their products for formal review — an expensive process which can take years to complete. Attaining these approvals requires heavy investment from metalworking fluid manufacturers, similar to the process pharmaceutical drugmakers undergo to receive FDA approval. A manufacturer’s approval does not just ensure compliance; it also represents an incredible dedication to quality.

Some fluid makers avoid this investment by conducting their own internal testing. Then, they can market a product as meeting the requirements of a particular OEM without going through the trouble and expense of seeking official approvals.

Why Using Officially Approved Metalworking Fluids is So Important

Using a cutting fluid not officially approved can be very risky for a supplier. Short term, this could destroy a supplier’s bottom line. Long term, they may lose their contract with an OEM and tarnish their reputation in the industry. Here’s what manufacturers can do to avoid confusion:

- If a fluid supplier has confusing language in their marketing material, such as “meets requirements” of a particular OEM, always ask for clarification about whether a product is officially approved.

- Request documentation from the fluid supplier confirming test results and official OEM approval.

- Contact the OEM directly for a list of their approved fluid suppliers.

The Master Fluid Solutions Difference

Master Fluid Solutions offers many products officially approved by OEMs in the TRIM® catalog, so customers can use an approved coolant specifically suited to their needs. With many products approved by multiple OEM’s, our customers who do work for several companies can focus more on their operation’s specific needs instead of just approval status. Master Fluid Solutions is continuously developing new fluids to meet the needs of our customers that will work on next-generation parts.

The aerospace and medical manufacturing sectors are rife with opportunity, as long as part and component suppliers are mindful of regulations and barriers to entry. To learn more about what to look for in OEM-approved cutting fluids and the benefits of TRIM® coolant, call +1 800-537-3365 or email us at [email protected].