Since the first TRIM® cutting fluid was introduced to the market in 1951, the entire product line has stood for quality, performance, and innovation. Serving the metalworking industry, the TRIM catalog has evolved to encompass straight oils, synthetics, semisynthetics, and even new advanced fluid categories like microemulsions and neo-synthetics.

To this day, Master Fluid Solutions continues to drive progress across its catalog, even in long-established categories like emulsion metalworking fluids. That’s why the company is now releasing the TRIM E860 emulsion in North America.

TRIM E860: A Game Changer for Precision Parts Manufacturers

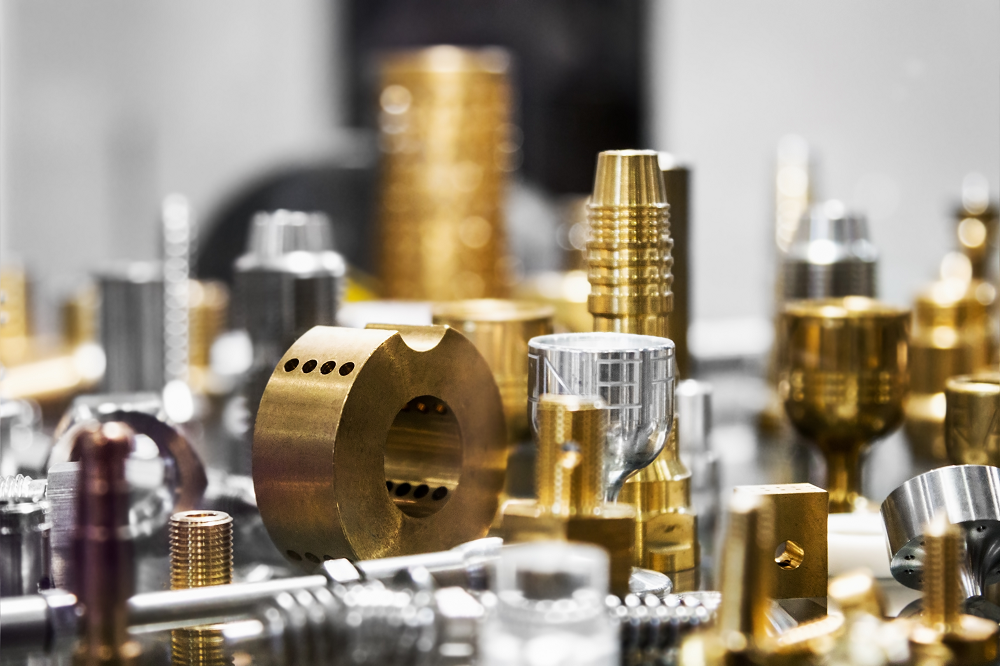

TRIM E860 is a heavy-duty emulsion that’s compatible with a wide range of materials, including both ferrous and nonferrous metals. The versatile product enables improved performance in almost every kind of cutting and grinding operation, making it a sought-after solution for manufacturers looking for a single fluid to use throughout their factory. In addition, the highly stable formula creates a predictable performance, making it the first choice for precision and consistent parts manufacturers.

The fluid’s signature stability doesn’t just improve performance with precision parts, but it also extends sump life. The low carryoff rate significantly reduces consumption. E860 rejects tramp oil for easy removal and maintenance. It also coats the machine, parts, and tools with a light, oily film for strong corrosion protection.

A History of Quality and Performance

E860 is new to the North American market, but it’s already been an incredible success in other regions around the world, including India and Southeast Asia.

“Our customers across the globe have already come to rely on TRIM E860 for its incredible sump life, stability, and ability to maintain high throughput and tool life during precision and high-production part manufacturing,” says Justin Geach, Global OEM and Business Development Manager. “As manufacturing continues to reshore and nearshore, it’s important to bring the same high-value solutions from other regions to the manufacturing base in North America.”

In South Korea, E860 has built a reputation for extending tool life far beyond competing solutions. In one case, a climate systems manufacturer suffered from poor tool life due to their previous cutting fluid’s ineffective lubricity. The low quality of the fluid resulted in high production costs and inconsistent parts, making it difficult to predict machine downtime and meet budgets for cutting tools.

After switching to TRIM E860, the customer completely eliminated corrosion and improved their tool life by 23.4%. Some specific drills, such as the 9mm tools, saw an even higher 40% increase in life.

In another case, an aerospace and automotive parts manufacturer in India suffered from an extremely high level of coolant consumption. The previous solution had a significant carry off rate, demanding frequent top-ups that increased usage and slowed down productivity. They also suffered from poor part finishes and resulted in a high scrap rate, further eroding profits.

After switching to TRIM E860, workpieces stopped developing tool marks, and finish quality improved dramatically. E860 also proved more effective at lower concentrations than the previous fluid, resulting in lower overall consumption. The customer reduced total coolant consumption by 22%.

A New Tool for Precision Parts Manufacturers in North America

TRIM E860’s reliable performance and high-quality formula make it an ideal solution for any type of precision and consistent part manufacturing, and will prove invaluable to the North American marketplace. To learn more about E860, or to schedule a trial in your shop, please contact us at 1-800-537-3365 or [email protected].